Re-Impact is a custom table tennis blade manufacturer based in Germany. They specialise in ultra light balsa blades, that offer unique playing abilities for specialist styles, while minimising strain and impact on the joints. Most blades played quite different on forehand and backhand, allowing you to optimise for certain rubbers, like pimples or anti-spin, and giving you optimum control over the pace of the game.

Through my dealing with Achim from Re-Impact via OOAK Table Tennis Shop, the Australian and SE Asia distributor for Re-Impact blades, I got to know him very well, and he kindly agreed to an interview. Questions are posed by myself and other members of OOAK Table Tennis Forum. Many thanks to OOAK Forum members for posting these questions!

I’d like to publicly thank Achim from Re-Impact for all the time and effort he spent, giving us these detailed answers! I’d also like to thank Kees from OOAK Forum for the great job in translating this very informative interview!

Interview with Re-Impact – 2010

Alex: Can you tell us a little about how you and your company Re-Impact got started? Who was part of setting it up?

Achim: My brother Eugen and I have together established our Firm as “A.Rendler GbR”. Our product at that time had the name “Re-Impuls”. We manufactured equipment specifically for the injured and handicapped sportsman, using my first patented model for Impulstechnology > Aircompartmentsystem. The invention was economically protected by EZN Erfinderzentrum Niedersachsen, since we had handed the industrial rights for mass production to a very well known table-tennis manufacturer in Völklingen; however, this special part of manufacture was excluded from the agreement. We had to furnish quite a number of additions and supplements in the same field, which had not been covered yet, to make the protection of the original patent complete and watertight. In 2002, however, we sold all rights to this firm, to end the contract with the exclusive representative we had then.

May 2002 we patented a new invention, the Re-Impact-technology, and the KSLS-system, the Ship screw-system and a new gluing-procedure. Since we used these technologies ourselves in A.Rendler GbR, we did not again sell the rights or parts of the patent. As is well known, the new Re-Impact product became a deposited trademark which up till now we have been doing well with.

January 2009 my brother Eugen unfortunately died completely unexpectedly of a heart-attack in a sauna. He had been looking forward so much to the company’s anniversary in November 2009…

After that I was alone in the firm until 31-5-2009. From 1-6-2009 the husband of my niece and godchild, Tobias Altmann, came as a partner into the firm which the both of us have since been able to continue very successfully.

Without my brother Eugen, however, it would not have been possible to manufacture the new invention Re-Impact for you, because Eugen was the one who invented, developed and built the special machinery we completely need for the Re-Impact technology; and he himself built these machines here in Lemförden on his own. He even designed the computerized units and the software needed for the manufacture of the blades in their rough form, and he has founded also the TT-forum, and did its maintenance. He was also the co-developer of the new Re-Impact technology, for he made my ideas of the invention simpler and practical, so they would actually work. So, naturally for me the death of Eugen is a bitter loss in every respect, for we worked together for 20 years in a boat&garden service of which I was an employee on health grounds, from 1989 on. In private and in business, from that date until his death, we were a well-forged team in every respect, and we completed each other wonderfully. I still miss my brother terribly…

Alex: Are there other people or manufacturers that you learned a lot from and influenced your progress, or did you develop all your ideas and designs yourselves?

Achim: We have independently developed on our own all the ideas and designs present in our patent and with our inventions from 2000 onwards we have revolutionised the existing medieval methods of construction in the table-tennis area. Actually, since then, other manufacturers have tried and more or less failed to copy our products, because they didn’t know how to understand our patent. That is why we have always successfully avoided having our basic research to become public knowledge, so the attempts of other manufacturers would literally break down.

Alex: I assume you used to play a lot yourself? Do you still play much now?

Achim: Of course, I have played table-tennis since I was 17. Even at that time already I had built myself a light-weight blade, constructed to improve my own play. But I quickly saw I was by nature far more a good basic trainer than someone to make a career with his sport. Since, I have taught the game of table-tennis to numerous children and also to handicapped people. Working with handicapped players of that latter category offered a diversion from my illness during my therapy for my breast-cancer in 1988, and I learned quite a lot with it which has determined much of my later inventions. My Brother Eugen, however, did not play. Instead, he was technically very gifted and filled his free time with model-building and designing security systems. He was also a gifted computer-engineer who built himself accessories to his computer for his special use. In 1998 we had difficulties with our boats&garden service firm due to the fact that more and more jobless people supplanted us in the garden business, which was a threat to the very existence of our firm. So we made a profession out of our hobbies. Eugen developed security systems for firms and I developed table-tennis blades. We became very successful in what we both did, so we used what the two of us had done already for the table-tennis sector, which by 2005 had become so profitable that we could make a living out of it. In the beginning we had difficulty in developing both the table-tennis business and its marketing because other table-tennis firms knew how to keep us out of it all. Only the World Wide Web and players telling each other about the service we provided, and then the exclusive manufacture for Dr.Neubauer GmbH brought a world-wide unstoppable break-through for our Re-Impact technology. Exclusive series are also made by us under our own supervision for Dr.Neubauer GmbH, viz. the Neubauer Spezial, and the Neubauer Combination Effect. Since May 2010 another product is made by us for Dr.Neubauer, the Neubauer Titan. This blade was developed after the Tachi and is a more offensive version using similar technology, but optimised for Dr Neubauer rubbers. It is designed more for a block/counterhit style, whereas the Tachi is more alround. There are still other exclusive series made by us; e.g. Schüett Re-Impact, Wallenwein, Ronin, Sebastian Sauer Spezial, Sebastian Sauer Allround, Dr. Regelmann Spezial, Wingeier Spezial, and so on.

Alex: What style of game do you play yourself? What blade/rubber combination do you use?

Alex: What style of game do you play yourself? What blade/rubber combination do you use?

Achim: As a result of surgery for my breast-cancer I lost in 1988 the left breast-muscle and some limbic glands under my arms. I had to change my style because of that and at first I protected my forehand with an antispin and later on with a long pip, Neubauer Roulette, for being right-handed I play my backhand on the left. Since then my backhand was my main area where I won my points hitting without a swing, whereas the forehand served to be insensitive to spin and seduce the opponents, who were not used to such a forehand, to serve mainly into my backhand area where I was strong. I have, by the way, tested and tried all my inventions myself. At the moment I play with the Taipan kombiversion, Katana, with D-tecs OX on the forehand and Hexer Duro 2.1 mm on the backhand, because I always test a new development when the newest has appeared on the market. I’d like to add that we are developing Tachi-Tuningversions, which I prefer too. Since for now I want to quiet down production for 18 months, there will appear no new products until then. But development, with me, of course never stops. From the ideas for development of my brother alone, which I am combining with my own ideas, a lot of fast-selling possibilities are coming up. The 18 months will do me good, allowing me to work quietly on something better still from another 25 different series for you.

Alex: How do you start the planning of a new blade? Do you look a specific style, and design a blade would best suit this style?

Achim: Actually, starting with an already developed product I always try by using the constructive criticism of other test-players to get rid of the initial flaws. That always brings me to completely different ideas for development, coming from the Re-Impact shelf. No, for myself I always try to create a still better blade and thus get to new series for development which I have tested by others. For this reason I can successfully advise practically any player of any type, because my advice for individually tailored models is always a matter of test first, buy later. Nobody will buy a “cat in the bag” from me!

Alex: Do you look at a new rubber, and optimise a blade for this? Or do you look at players, and design a blade that suits their style best.

Can you give an example?

Achim: No, nothing of the kind. The rubber-market is a difficult factor with Re-Impact products, since the manufacturers seek development by enhancing rubbers instead of blades. Blades of other firms are still made in the old-fashioned way. At the most a blade may be made stiffer or simple ideas about the grip are incorporated in a medieval production of blades, often using alien substances instead of wood. Rubbers are growing heavier and light-weight blades have to compensate this. This boosting of the rubbers is frequently a problem for Re-Impact products, since these rubbers are designed for better success in the same way as our Re-Impact blades, which produce an inner membrane-activity from resonance. Relative to the force of this inner membrane-activity, the outer membrane-tensions of the rubber will be neutralized by them. This is why the test-results in forums are very important to analyse the combination of rubber-counter tensions on a Re-Impact product.

Alex: Providing customised blade seems to be quite a new thing in table tennis. Do you think there is a good market for customised blades?

Achim: Of course, for the best example is Rendler Re-Impact. I have already made 2500 individually customized blades, each with its own code. If you are able to supply your individual code, you will get a blade identical to the previous one, which will play 75% identically.

Alex: If there were no constraints (on wood percentage etc:) a manufacturer with customisation capabilities could produce a blade for a particular style significantly better than those available at the moment?

Alex: If there were no constraints (on wood percentage etc:) a manufacturer with customisation capabilities could produce a blade for a particular style significantly better than those available at the moment?

Achim: Well, I don’t think manufacture from alien substances would be better than from pure wood, like our products are made of according to the manufacturers brand list T4. More likely, manufacturers lack ideas for wood-construction, because they have forever tried to improve the rubbers and left out the actual soul of the game, viz. the wood-construction, which we concentrated on with Re-Impuls and later on with Re-Impact. The conventional development of blades is at least a decade behind compared to what we are developing now. That is why it is so difficult for them to make products as good as ours, because there are no applicable matrices of reference for conventional products and we keep our manufacturers’ secrets. These matrices are of course not even included in our patents. LOL

Alex: You use more numbers than other manufacturers to indicate the characteristics of your blades (Speed, control, etc). Can you explain a little what they mean? How do you work out those numbers? Do you have a test setup, or do you work them out from testing them in practice yourself?

Achim: Naturally there are ways to research our products, which we first use for comparing sound waves and their sinus-curves and afterward apply to the test results of many comparable test-persons. The reference-values we have got from this, having been used consistently from the beginning, today form important references to get to new blade-constructions which could be even better as everything we offer in our Re-Impact sector. The spin-value is therefore an important factor for our clients to be able to compare Re-Impact blades as to their suitability for spin or block and counter drive. Ball-control is however comparable directly to all conventional available blades which are not by Re-Impact, for what we develop and sell specially for you is pure ball-control. But many have come to be convinced that they have more spin and catapult with Re-Impact blades than with other products normally sold, and others believe rather that this is not the case. Anybody who does not believe it may look upon our spin-values as an advertisement-gag we use. But we would not be fool enough to make our basic technology available for other manufacturers. They would do better to do research of their own instead of make cheap copies.

Alex: Why is the shape of your blades different to most standard sizes from other manufacturers?

Achim: This special blade-shape of Re-Impact is just one part in a series of in sum 14 inventions linked together. Its purpose is to bring down the feedback ratio, in order to put less pressure on and tension in wrist and shoulder. The shape also serves to improve and direct sound waves of special reflections which the KSLS-system in turn should distribute over the veins of the wood to a distinct degree, for our products are made in a similar way as musical instruments. It is about hearing harmonics (sound quality of the wood) and feeling waves of motion that are primarily directed to thumb and index-finger. Therefore the shape of the blades of Re-Impact resembles one adapted to an outside mirror.

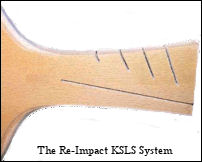

Alex: What do the little cut-outs on the side of the handles do?

Achim: The little cut-outs reduce every sort of individual vibration in the wood by step-wise getting longer towards the end of the handle, so that few disturbing vibrations arrive along the longitudinal axis of the tuning-fork, which should refine the sound quality of the wood by hearing and thereby the ball control in the higher frequencies. At the same time it serves for being able to discriminate between the right-hand and left-hand side of an a-symmetrically formed wood for match players, or, with symmetrically formed Re-Impact blades, for being able to discriminate between two independent playing surfaces which ascertains identical playing qualities on the forehand and the backhand of these systems.

Achim: The little cut-outs reduce every sort of individual vibration in the wood by step-wise getting longer towards the end of the handle, so that few disturbing vibrations arrive along the longitudinal axis of the tuning-fork, which should refine the sound quality of the wood by hearing and thereby the ball control in the higher frequencies. At the same time it serves for being able to discriminate between the right-hand and left-hand side of an a-symmetrically formed wood for match players, or, with symmetrically formed Re-Impact blades, for being able to discriminate between two independent playing surfaces which ascertains identical playing qualities on the forehand and the backhand of these systems.

The KLSL-System is the basis for our special marketing: “The wonder-blade from North-Germany!”

The following explanation is unique in the construction of blades for match play.

Every symmetrical Re-Impact blade has two playing-surfaces which, identically on forehand and backhand, differ only as to speed, catapult and higher or lower ball-control respectively. The cuts in the handle mark, with a symmetrical layering of the wood, therefore always the forehand of a right-handed player and the opposite backhand side of a right-handed player or in reverse the forehand of a left-handed player, if the cuts in the handle either point at the inner hand (first playing surface with identical playing qualities on forehand and opposite side), or to the fingers, by rotating the blade 180 degrees (second playing surface with identical playing qualities on forehand and opposite side, i.e. backhand).

The first playing surface has been constructed according to the concept of the whole blade and its plies in such a way that a great number of sound waves produced by making contact with the ball influence the speed thus, that the speed ratio is a little slower or all-rounder than in the second surface which works in the reverse way and vibrates less. The consequence of this is that the first surface has less catapult and the whole blade gets more feel as the second surface, whereas this second surface with its fewer vibrations produces more speed and catapult which leads to clearly less feel. Such a blade-concept can be seen as unique in the world.

The combi-blades also have these qualities. But they are decreased by the difference in speed of the outer plies or improved combined speed reduction in the backhand. A good technical player will however in his play notice well the different influences which offer advantages especially to pips’ players or normal players who like for reasons of control to use a speed reduced backhand. How this precisely works technically remains, however, our trade-secret.

Alex: Almost all your blades are significant’ lighter than standards blades. Do you think this is better for most players?

Achim: It is a special advantage for older players who are less dynamic or for players with damaged wrists, elbows or shoulders to be able to play with a blade for match play which has been adapted to their physique. This is also the case with children who with Re-Impact equipment will not be overburdened. For the rest is it in every case an advantage for all players who with less weight get less tired when training or competing. I could easily make a blade heavier if someone wished it, but most people don’t. Playing with Re-Impact means loving to get at the ball quicker and be able to play with more risk, which restrains the opponent and does hardly allow him to play his own game.

Alex: What weight range do you think is ideal? Does this depend on the player’s strength?

Achim: An attacking player ideally uses a total weight of at the most 140 grams. But for an injured player who has been injured once the blade cannot be light-weight enough, in order to totally avoid cramping. But it hardly depends on the aptitude of a player; far more on the physical condition of his body.

Alex: We know you make blades for Dr Neubauer and perhaps other brands as well. Would you rather makes blades for another brand, or makes blades under your own brand?

Achim: Of course I prefer manufacture for my own brand. Our marketing is, however, limited so we cannot reach every market; therefore exclusive products are necessary to familiarize the whole world with Re-Impact, as history has clearly shown.

Alex: How are your expertise and creativity used best and most?

Achim: Of course in our own Re-Impact products. I continuously advise individual clients, based on their own technical demands, or weaknesses, about how special models can be made by combining different Re-Impact products.

Alex: Some of your blades are best suited for antispin, some for long pimples. What are the main differences in blade requirements for antispin and long pimples?

Achim: Different LPs already demand different requirements, and it is the same with frictionless versus grippy anti’s. For antispin rubbers wood-constructions are best which offer a block-counter-effect on both playing surfaces or combine hard/soft-concepts on the backhand and the forehand. For blades which are to be played primarily with grippy LPs, the best value to watch is the spin value or spin sensitivity of the surface the LP is used on, for a grippy LP can only produce good spin-reversal if the blade is capable of producing high spin values with this surface. Here, again, the spin value is useful which is standard for the various Re-Impact products and very important for players using pips who will be able to find the centerpiece of their playing technique and therefore the best-suited equipment with Re-Impact.

Alex: Which are the three product that you’ve made, that you are most proud of, and why?

Achim: On principle always the three latest developments, but since I have photographic memory I also always remember previous developments when I want to incorporate their specific playing qualities in new developments. In my brother’s notes there are many development-series, however, that I have not yet completely analyzed and understood. The Taipan und its off-spring of Katana, Mephisto, Tachi, Eugen Memo, Intro all come from these notes, and their further development included combination with my own inventions. So it is more than logical that I give honor to my late brother and do not praise myself for what he has achieved, for my brother was in his lifetime not well known because he personally did not want to.

Alex: The Tachi is probably been the most talked about blade outside Germany. We know you recommend to use Dtecs on this blade, but many of us are wondering how suitable this blade is to other long pimple rubbers?

Achim: Other LPs are only a problem when they are to slow. The Tachi should be primarily used with medium fast to fast LPs. But according to my tests, few other LPs are as insensitive to spin on the Tachi as the Grass D-tecs.

Alex: Do you perhaps have a more suitable blade for other types of pimples, for those that play the same style?

Achim: Oh yes, of course there are the following choices: Medusa, for fast offensive forehand play and a backhand completely insensitive to spin with for instance Donic Alligator. The Medusa is also excellent with Stiga Royal on forehand for block-counter-hit and Alligator on the backhand (defensive technique). Who likes to play aggressively with pips on both sides should choose the Backspin Pressure. Both blades are of course also suitable for your Tom Dick and Harry offensive players who use a soft antispin rubber on the backhand (= Backspin Pressure), who use a hard antispin rubber on the backhand (=Medusa or Achim Select M3), who use topspin with their backhand, but prefer a controllable yet more aggressive backhand ( = Backspin Pressure), who use a defensive inverted rubber on the backhand and like be insensitive to incoming spin (= Medusa). Actually, every blade which we have designed for grippy LP is at the same time because of its very high spin production all the more suitable for two-winged topspin players, or also for block&counter players who like a very controlled block. With the Mephisto one can play almost any LP in a totally controlled way, because it is the very blade for players who want to be able to return each and any ball. The Mephisto is, however, again also best suited for topspin players who primarily go for topspin kills. The thickness would then have to be at least 1.9 mm. The same is true for the Taipan which needs a polished playing technique and therefore is not the best choice for everyone. Using the Grass D-Tec ox, the Taipan is however the most dangerous blade, if you are able to use the old technique for frictionless LPs with it. If you have no command of this technique, you should take the Katana instead, which is the Taipan combination blade and has the Taipan’s forehand design, but is much more forgiving for mistakes than the Taipan.

Achim: Oh yes, of course there are the following choices: Medusa, for fast offensive forehand play and a backhand completely insensitive to spin with for instance Donic Alligator. The Medusa is also excellent with Stiga Royal on forehand for block-counter-hit and Alligator on the backhand (defensive technique). Who likes to play aggressively with pips on both sides should choose the Backspin Pressure. Both blades are of course also suitable for your Tom Dick and Harry offensive players who use a soft antispin rubber on the backhand (= Backspin Pressure), who use a hard antispin rubber on the backhand (=Medusa or Achim Select M3), who use topspin with their backhand, but prefer a controllable yet more aggressive backhand ( = Backspin Pressure), who use a defensive inverted rubber on the backhand and like be insensitive to incoming spin (= Medusa). Actually, every blade which we have designed for grippy LP is at the same time because of its very high spin production all the more suitable for two-winged topspin players, or also for block&counter players who like a very controlled block. With the Mephisto one can play almost any LP in a totally controlled way, because it is the very blade for players who want to be able to return each and any ball. The Mephisto is, however, again also best suited for topspin players who primarily go for topspin kills. The thickness would then have to be at least 1.9 mm. The same is true for the Taipan which needs a polished playing technique and therefore is not the best choice for everyone. Using the Grass D-Tec ox, the Taipan is however the most dangerous blade, if you are able to use the old technique for frictionless LPs with it. If you have no command of this technique, you should take the Katana instead, which is the Taipan combination blade and has the Taipan’s forehand design, but is much more forgiving for mistakes than the Taipan.

The Tachi’s forehand has the same ball handling the Mephisto’s does and is because of its being light-weight really the top-blade for pips players, since it is very easy to handle and very forgiving. As the forehand is soft, however, and completely without catapult at that, it is only suitable for medium hard rubbers (38 degrees or more). Instead, the Katana is suitable for every thinkable rubber of any hardness. The disadvantage is that on account of its design it is much heavier than the Tachi.

On top of this there are many older symmetrical developments of which I am just as proud; in fact, I am proud of everything I ever made. But at the time the most exciting thing for me is to work out the as yet unknown developments of my brother, because there is an enormous potential there.

Alex: What are your future plans?

Achim: I think you will see when you will see. As for the level technology, everything is already old when it comes out new, since I always have new plans at the moment a product appears. And I think it is important to take the necessary time in order to be able to present to you next time a model which is better than everything already available. In at the most 18 months it will be ready. Until then you will have to be content with my available products, alas.

Yours truly, Achim Rendler

Note: OOAK Shop is the authorised distributor for Re-Impact in Australia and SE Asia

rely i appreciate all the things!